Automation is the key to unlocking higher productivity and efficiency in manufacturing. Our IoT system automates various stages of the manufacturing process, eliminating repetitive and error-prone tasks. By leveraging automation and real-time analytics, manufacturers can achieve faster production cycles, lower defect rates, and optimized resource utilization. Our system focuses on improving efficiency parameters such as Overall Labor Effectiveness (OLE), Overall Equipment Efficiency (OEE), and other similar key performance indicators. By streamlining operations and leveraging Big Data analytics, manufacturers can maximize their production output and minimize downtime while making data-backed improvements.

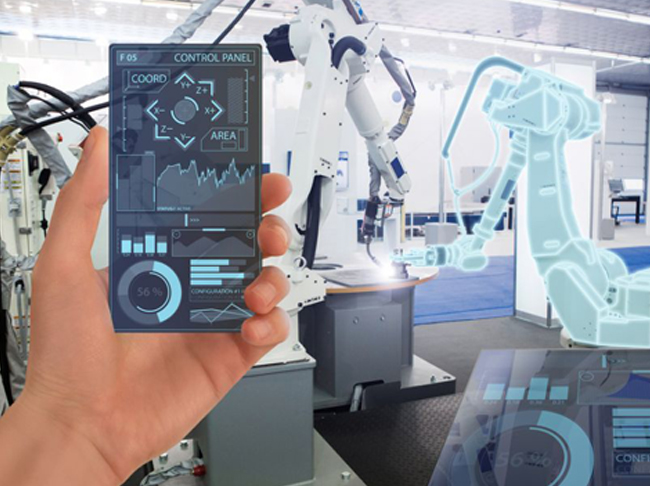

Our IoT system includes a comprehensive and user-friendly analytics dashboard that provides manufacturers with actionable insights and real-time visibility into their production processes. The intuitive dashboard consolidates data from various sources, including sensors, machines, and production lines, and presents it in a visually engaging format. With customizable charts, graphs, and reports, manufacturers can monitor key performance indicators, track production trends, and identify areas for improvement. The advanced analytics dashboard empowers decision-makers to make informed decisions, optimize operations, and drive continuous process improvement.

Our IoT system incorporates powerful Big Data analytics capabilities that enable manufacturers to extract, analyze, and derive actionable insights from large volumes of data generated throughout the production process. By processing and analyzing diverse datasets, including sensor data, operational data, and historical records, our system helps identify patterns, optimize workflows, and make data-driven decisions to improve manufacturing efficiency and quality.

At Nexgensis, we are committed to enhancing manufacturing processes and driving operational excellence through the power of vision-based AI, Big Data analytics, and automation. Our IoT system has empowered numerous companies to achieve significant improvements in productivity, quality, and efficiency. From automating complex assembly tasks to ensuring precise product inspection and leveraging data analytics, our technology has helped our clients reduce costs, minimize defects, and streamline their production workflows. Explore our case studies and success stories to discover how our IoT system can transform your manufacturing operations.

Our IoT system utilizes a robust technology stack to deliver exceptional performance and reliability. It combines state-of-the-art hardware components, advanced software platforms, cloud services, and scalable Big Data analytics infrastructure. With our proprietary algorithms and innovative approaches, we have created a solution that exceeds industry standards and ensures seamless integration of vision-based AI, Big Data analytics, and automation into your manufacturing ecosystem.

Nexgensis stands at the forefront of technological innovation, delivering a diverse array of tailored products and services designed to meet the unique needs of our clients. Our comprehensive offerings include cutting-edge solutions such as

Vision AI is employed for precise defect detection.

Traceability solutions enhance monitoring and tracking in manufacturing lines.

Streamlined Batch Processing ensures operational efficiency.

Supplier Relationship Management (SRM) fosters strategic collaborations.

Our services extend to machine maintenance and ticketing, ensuring optimal performance and longevity.

At Nexgensis, we are committed to pushing the boundaries of technology to provide innovative and customizable solutions that drive excellence across various industries.

By implementing our IoT system for Vision-Based AI, Big Data Analytics,

and Manufacturing Automation, manufacturers can unlock a host of benefits

Automate manual tasks, optimize workflows, and reduce human error, leading to improved overall efficiency. Enhance parameters such as Overall Labor Effectiveness (OLE) and Overall Equipment Efficiency (OEE).

Eliminate waste, optimize resource utilization, and minimize downtime, resulting in substantial cost savings.

Perform precise product inspection, reduce defects, and maintain consistent quality standards.

Perform precise product inspection, reduce defects, and maintain consistent quality standards.

Stay informed about production processes, identify bottlenecks, and address issues promptly.

Stay informed about production processes, identify bottlenecks, and address issues promptly.

Ensure adherence to industry regulations and standards, including quality control, safety, and environmental requirements.